spawarka mig Spawarka Mig i mag Co2 MIG-350HD

| udział | |

|---|---|

| Katalog produktów | wszystko |

| marki | TOPWELL |

| Specyfikacja produktu | MIG-350HD |

| Znamionowe napięcie wejściowe | 3PH ~ 400V + 15% |

| MAX.Load Power Capacity | 15,26 KVA |

| Znamionowe wyjście | 350A / 31,5V |

| Maksymalne napięcie obwodu otwartego | 70V ~ 80V |

| Efektywność | 85% |

| Mechanizm podawania drutu | 4 Walce |

| Zakres prędkości podawania drutu | 0-25m / min |

| Gwarancja | 1 rok gwarancji |

| Wymiar | 960 x 420 x 1400 mm |

| Waga | 80 kg |

| port | Ningbo Szanghaj |

| płatność | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Zaktualizowano | 2026/2/18 |

-

MIG-350HD

Synergic, MIG Welder

-

Application:

Metal fabrication workshops

Shipyards and offshore industry

Chemical and process industry

Steel structure workshops MMA(Stick) -

Processes:

MIG

MAG

Flux-Cored

MMA(Stick) -

Input Power: 400V, 3-Phase

Rated Output at 40°C (104°F):

350A at 31.5V @60% Duty Cycle

Weight: 80KG

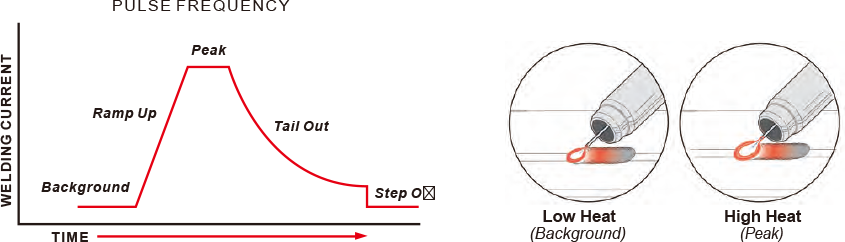

PULSE MIG

Pulsed MIG varies weld current between peak (high heat) and background (lowheat) current to provide better control of heat input, which minimizes warping and burnthrough on thin materials. Pulsed MIG also enables flat,horizontal, verticalup, or overhead welding without a slag system.Optimized GMAW-P waveforms are readily available to use on aluminum,carbon steel,high strength low alloy steel, stainless steel,and nickel alloys.

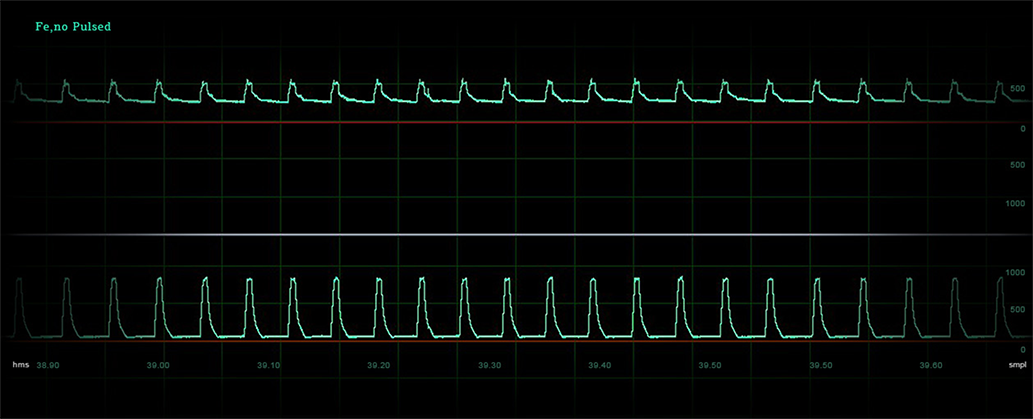

The advantage of Wave-form Control System

The latest technology of Waveform Control System, can perfectly control the output of welding power and get the precision Arc performance. The wire melting droplet transfer cycle is very clear, the welding beam is very clean and very few spatters during welding.

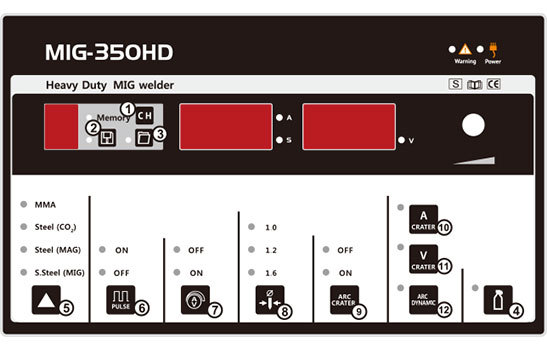

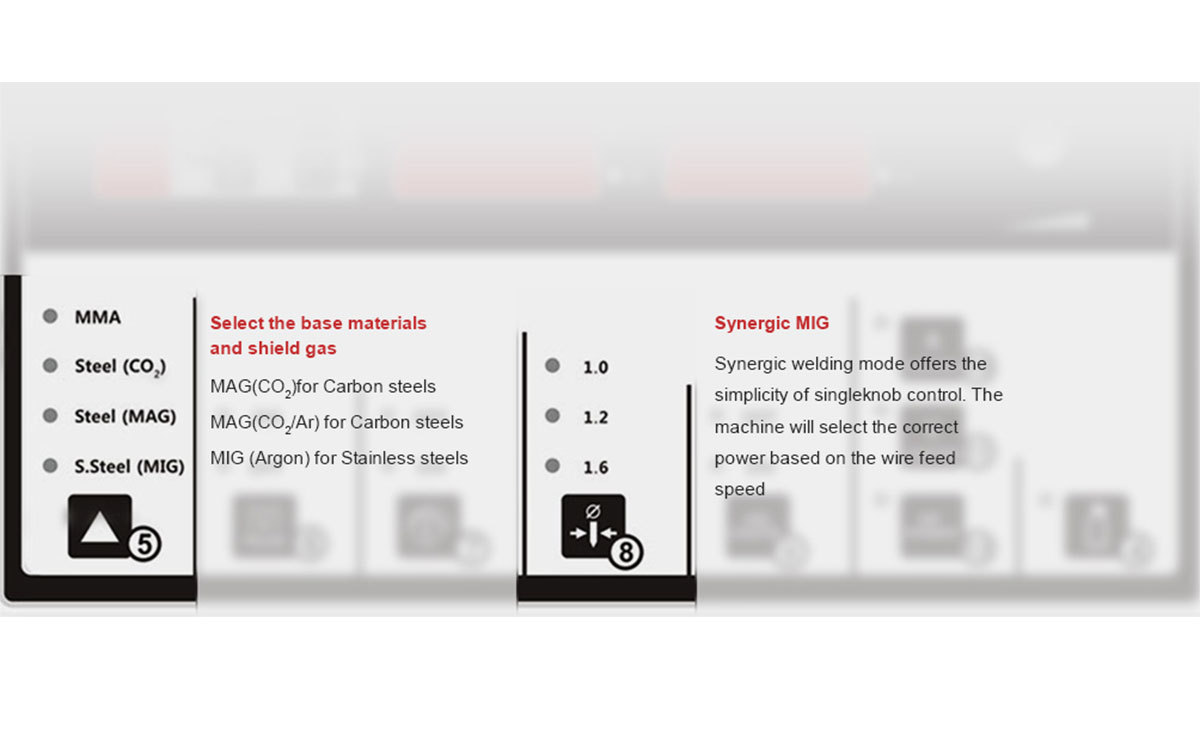

General View of Control Panel

1.SELECT the Memory channel

2.OPEN the parameter of selected memory channel

3.STORE the setting to Memory channel

4.Push to Check Gas

5.Welding Process

MMA,

MAG(CO2)for Carbon steels

MAG(CO2 /Ar) for Carbon steels

MIG (Argon) for Stainless steels6.Pulse MIG: ON/OFF

7.Synergic function ON/OFF

8.Synergic setting (select wire diameter)

9.Arc Crater: ON/OFF

10.Select to adjust the Arc Crater Current

11.Select to adjust the Arc Crater Voltage

12.Arc Dynamic controls

Classical MIG/MAG

In classic mode, MIG / MAG welding is carried out in inert gas with automatic wire feed.With this mode, a high welding speed and excellent quality are offered without any extra costs in the processing of ferrous metals, as well as various steels.

-

-

Item No MIG-350HD Rated Input Voltage 3PH ~ 400V ±15% Max. Load Power Capacity 15.26KVA Rated Duty Cycle(40℃) 60% MIG: 350A/31.5V MMA: 350A/34V 100% MIG:300A/29V MMA:300A/32V Welding Current/Voltage Range MIG: 10A/14.5V~350A/31.5V MMA:10A/20.4V~350A/34V Open Circuit Voltage 70V~80V Power Factor 0.85 Efficiency 85% Pre-Gas Time Preset Flow-Gas Time Preset Wire-feed Mechanism 4 Rollers Wire-feed Speed Range 0~25 m/min Wire Spool Capacity 300mm (15kg) Filler Wires Ø (mm) Fe, Ss: 0.8~1.6 mm Dimension 960X420X1400mm Weight 80KG Water-cooling Unit: WC-150 Operating Voltage 230V 50/60Hz Rated Power 260W Cooling Power 1.5KW(1L/MIN) Maximum Pressure 0.3MPA/60HZ Recommended Cooling Liquid 20%~40% ethanol/water Tank Volume 6.5L -

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly