Maszyna do cięcia plazmowego CNC Inverter CUT-100H HF / NON-HF

| udział | |

|---|---|

| Katalog produktów | wszystko |

| English details | Inverter CNC Plasma Cutting machine PowerCUT-100H cnc plasma cutters for sale |

| marki | TOPWELL |

| Specyfikacja produktu | CUT-100H |

| Znamionowe napięcie wejściowe | 3PH ~ 400V ± 15% |

| Znamionowa wartość wyjściowa produktu | 30-100A |

| Maksymalne napięcie obwodu otwartego | 17,8KVA |

| Efektywność | 85% |

| Maksymalny prąd wejściowy | 340 / 460V, 52 / 38A |

| Znamionowe napięcie wyjściowe | 120V |

| Certyfikaty | CE, RoHS |

| Gwarancja | 1 rok gwarancji |

| Wymiary | 680X310X650MM |

| Waga | 42 KG |

| port | Ninbo / Szanghaj |

| płatność | L/C, D/A, D/P, Western Union, MoneyGram, T/T, Paypal |

| Zaktualizowano | 2026/2/18 |

-

CUT-100H

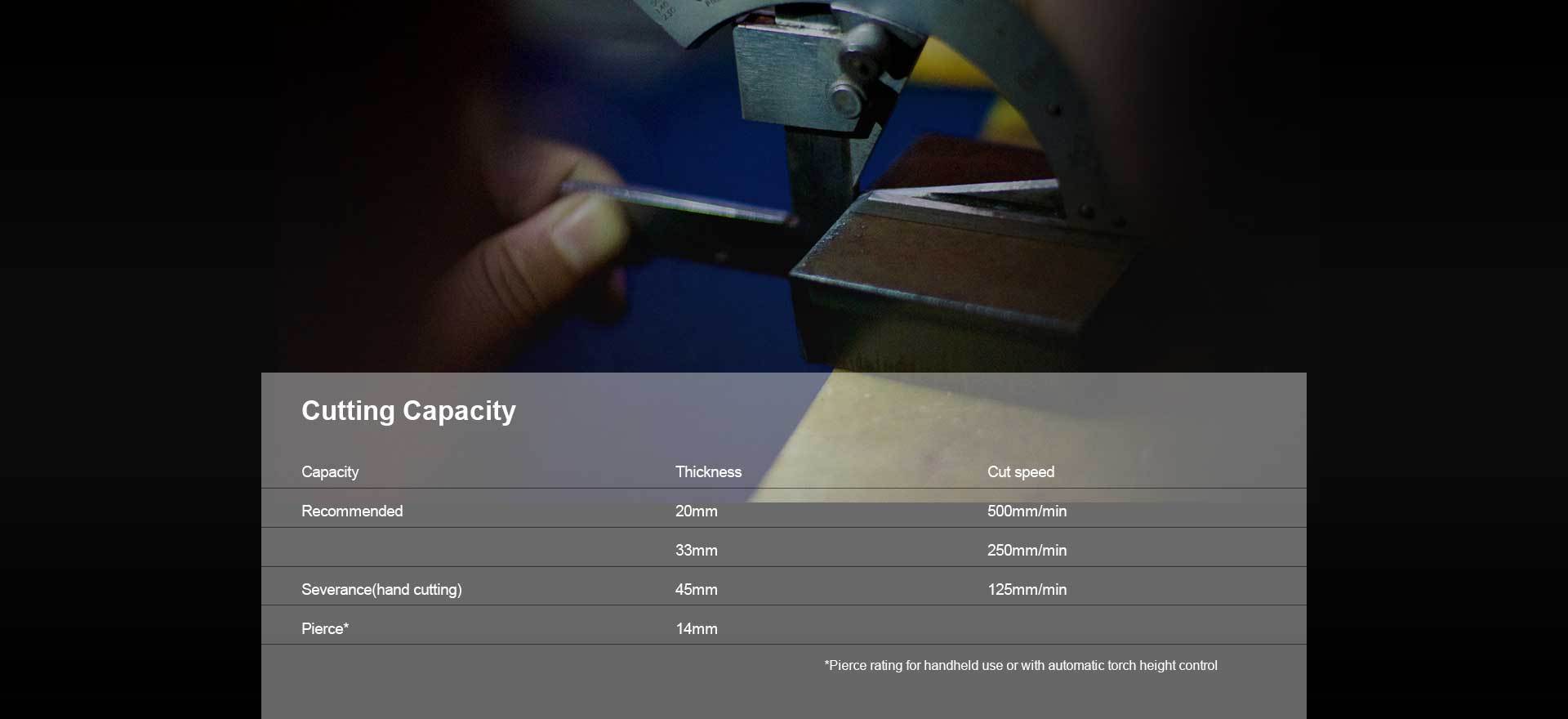

Professional-grade power plasma for cutting 20mm thickness metal @500mm/min

-

Light Industrial Application:

Home workshop

Metal workshops

Light fabrication

Repair and maintenance -

These Materials:

Mild Steel

Brass

Stainless Steel

Copper

Aluminum -

Input Power: 340-460V, 3-Phase

Amperage Range: 30-100A

Rated Output at 40℃ (104℉):

100A at @60% Duty Cycle

Weight: 42KG

Maximum productivity

Cutting 20mm@500mm/min ensures the maximum pro ductivity(optional torch).

Finish jobs much faster with cut speeds greater than oxyfuel.

Spend less time on grinding and edge preparation due to superior cut quality.

Easy-to-use with versatile design

Very easy to use, even for first time operators.

Non-HF type available: Starts without high-frequency so it will not have electromagnetic interfere.

Tackle different jobs with multiple, easy-to-use torches.

Easy to work with CNC system.

Low operating cost

Reduce costs with long consumable life and more uptime.

High power efficiency lowers energy consumption.

Rugged and reliable

TOPWELL Certified reliability ensures performance in the most demanding environment.

Powercool design cools internal components more effectively for long system life and improved uptime.

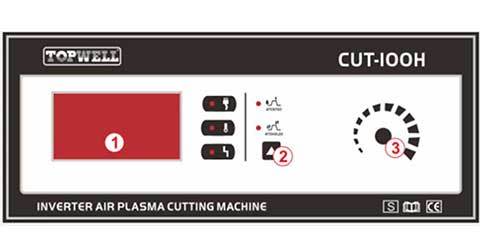

General View of Control Panel

-

1.Ammeter/Voltmeter Display

2.Encoder Control

3.Mode:2T(STD)/4T(HOLD)

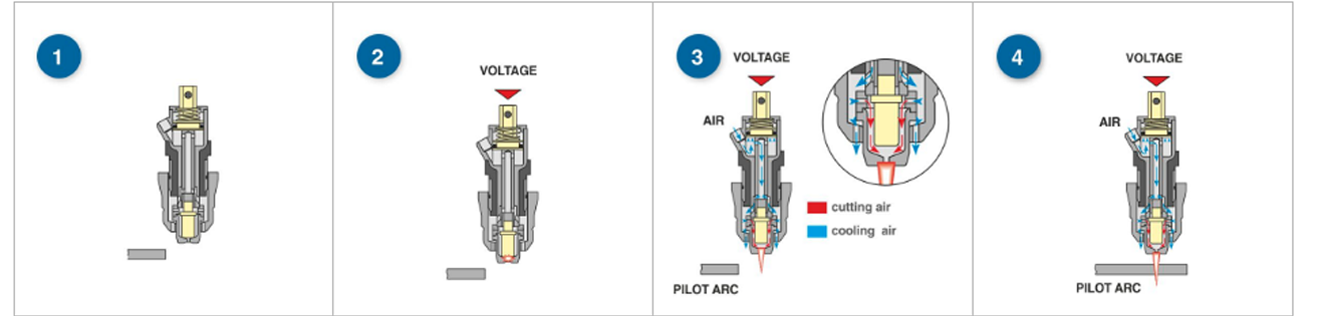

Non-HF Arc Ignition system

- Torch off.

- By pressing the trigger the torch will be fed by the current thus causing a temporary short circuit betweenelectrode and tip.

- The air then pushes up the small piston, thuscreating, between the electrode and the tip, the distance needed to strike the pilot arc.

- By positioning the torch on the part to be cut, theplasma arc will strike.

Torches with pilot arc cut in without high frequency.

Less electromagnetic disturbance, with consequent absence of problems for any electronic, radio, television, telephone and computer systems in the vicinity of the cutting positions.

Less electric stress on the torch - and on the respective connecting cables - due to the absence of the high voltage necessary for striking the arc Greater simplicity in comparson with other torches(without high frequency) on the market,with a consequent decrease of the risks of jamming in the mechanical pneumatic movement for striking the arc. Subject to wear (electrode, tips, nozzles, diffusers etc.), thanks to the better cooling of the torch obtained by reducing the insulating thicknesses (without endangering the safety parameters).

-

-

Item No CUT-100H Input voltages (±15%) 340-460V, 3-PH, 50-60Hz Max Input current 340/460V, 52/38A Output current 30-100A Rated output voltage 120V Duty cycle @ 40° C (104° F) 60% @100A 100% @80A Open circuit voltage (OCV) 280V Dimensions 680x310x650mm Weight 42kg Gas supply Air (clean, dry and oil-free) Recommended gas inlet flow rate/pressure 0.4-0.6Mpa Power supply type Inverter – IGBT Electrical efficiency 80% Max. Load Power Capacity 17.8KVA Certifications CE, RoHS Warranty Power supply: 3-year Torch: 1-year - ACCESSORIES

-

-

Q:Are you a factory or a trading company?

A: We are factory with more than 10 years manufacturing experience and we provide perfect OEM and after-sale service.

Q:How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments. For those orders less than 1000USD, we accept PayPal to pay.

Q:How about your warranty?

A: We offer 3-year product life guarantee ,and a generous 1 year warranty on al purchases that begins with the bill of lading.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are urgent to get the price,please send the message on trade management or call us directly