dom / wszystko / Plasma Cutting / MAX Series /

High Definition Plasma Cutting Plasma Source HD 300 MAX with TP300MAX Oxygen Process hy replacement

High Definition Plasma Cutting Plasma Source HD 300 MAX with TP300MAX Oxygen Process hy replacement

Aby uzyskać więcej informacji

DETAILS

MAX300

Extra-Definition, Maximized productivity across a broad range of application needs, from very thin to heavier thicknesses.

Cutting Capacity

|

Mild Steel Cut Capacity

|

Thickness

|

|

Dross free*

|

35mm |

|

Production pierce

|

42mm

|

Maximum cutting capacity | 70mm |

Superior Cutting Performance

Optimized gas parameters are set and controlled by the software. With Oxygen/Air/N2/H35 plamsa gas, the HD MAX series plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life.

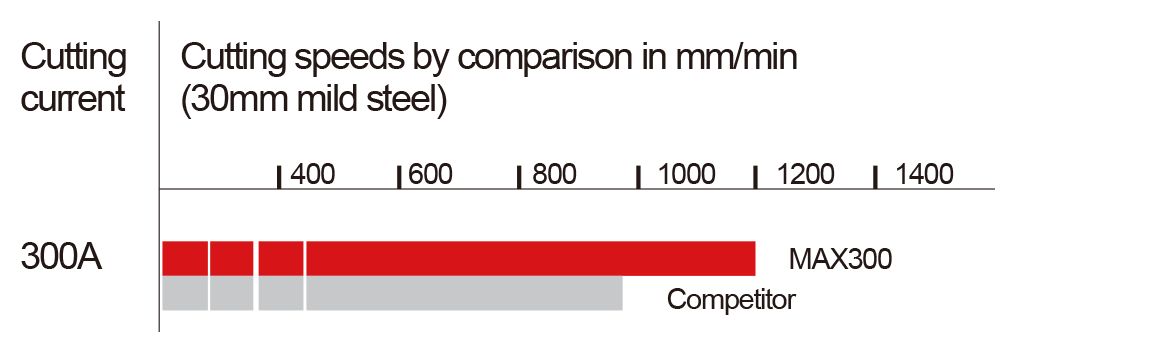

Maximized Productivity

· MAX Series provides faster cutting speed to maximize productivity.

· Engineered with 100% duty cycle for the most demanding production environments.

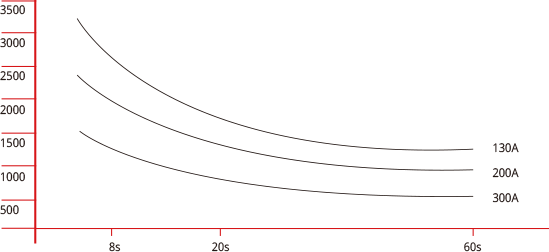

Long-life Consumables

The MAX300 system ramps current and gas flow up and down in a tightly controlled manner to reduce electrode and nozzle erosion.

Reducing electrode and nozzle erosion enables more consistent cut quality over a longer period of time, while providing a significant reduction in operating cost.

· Ignitions per cutting time in seconds

· 20 second duration

· MAX300 : 810 times

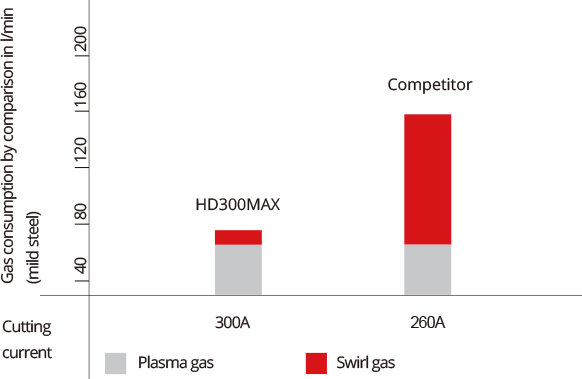

Efficient Gas Supply

The MAX300 plasma systems significantly increase the efficiency of gas and reduce the gas consumption.

· Cutting Current: 300A

· Gas consumption:

Plasma Gas: 60 l/min

Shielding Gas: 75 l/min

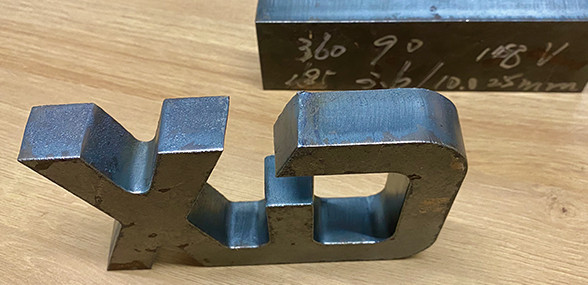

Bevel Cutting Technology

Bevel Cutting Technology is a performance application for mild steel. Factory tested and easily implemented, it takes the guesswork out of the plasma bevel-cutting process. With Bevel Cutting Technology, setups for new jobs are quick and results are accurate and consistent.

· 1 iteration

· Using True Bevel

· Acceptable part and ready to start production

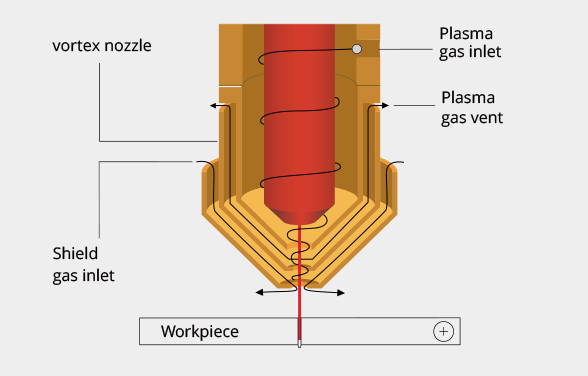

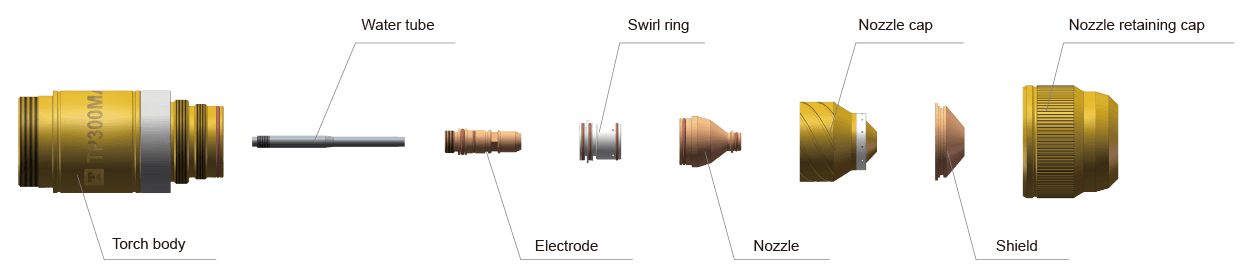

Refined Torch System

· Vented nozzle technology aligns and focuses the plasma arc.

· High Definition Cutting enables powerful precision cutting for superior quality and consistency on mild steel.

· High Definition delivers superior quality to thin stainless steel cutting.

VIDEO

SPECIFICATIONS

Machines

|

Product Name

|

MAX300

|

|

Cut angle(ISO 9013 range*)

|

2

|

|

Weldability

|

Ready to weld

|

|

Plasma Gas

|

O2; Air; N2; H35

|

Shield Gas | O2; Air; N2; |

Product Weights & Dimensions

|

Dimensions(L*W*H)

|

450*800*950mm

|

|

Net Weight

|

252KG

|

Basic Specification

|

Input Voltage

|

380V/400V, 3PH, 50/60Hz

|

|

Input Power

|

75KVA

|

|

Rated Output Voltage

|

50~200VDC

|

|

Rated Output(40℃) 100%

|

300A

|

Open Circuit Voltage (OCV) | 430VDC |

* ISO 9013 is a standard that defines cut quality of thermally cut parts. The lower the range (range 1 is the lowest), the smaller the angle on the cut face. Cut angle in range 4 is better than in range 5.

YOU MAY ALSO NEED

TP300MAX consumable Kit

TP260XD

TP260XD Consumable Kit

Gas Console (H35/N2)

Gas Console (Air/Air)